Materials And Components For Flat Panel Screen

A light-emitting diode (LED) screen (LED Panel Screen) a semiconductor light source that emanates light when current courses through it. Electron in the semiconductor recombines with electron openings electron, delivering energy as photons. The shade of the light (contrasting with the energy of the photons) constrain from the energy require electrons to cross the band opening of the semiconductor. You obtain White light using various semiconductors or a layer of light-releasing phosphor on the semiconductor contraption.

Showing up as down-to-earth electronic parts in 1962, the most punctual LEDs produced low-power infrared (IR) light. The primary obvious light LEDs are of low force. They have a limitation of red. Current LEDs are accessible across the noticeable bright and infrared frequencies, with high light yield. In early times, it was mainly used to replace incandescent bulbs in indicator lamps. However, ongoing improvements have created high-yield white light LEDs appropriate for room and outside zone lighting. LEDs have prompted new shows and sensors, while their high exchanging rates are valuable in cutting-edge interchanges innovation.

LED panel screens have numerous benefits over radiant light sources, including lower energy utilization, longer lifetime, improved actual heartiness, more modest size, and quicker exchanging. You can use them in different applications namely, aeronautics lighting, pixie lights, car heading, publicizing, general lighting, traffic lights, camera streaks, lit backdrop, plant development light, and clinical gadgets.

While you compare it to a laser, the light radiated from a LED is neither frightfully coherent nor even profoundly monochromatic. Nonetheless, its range is adequately limited in that it appears to the natural eye as an unadulterated immersed color. Also, dissimilar to most lasers, its radiation isn’t spatially intelligible. So it can’t move toward the extremely high splendor normal for lasers.

Introduction

Many groundbreaking settings and temples are currently buying LED screens to increase their standards. They are trying to compete with the ever-rising technology.LEDs are magnificent devices, that have taken the world by storm and have grown famous all over the world in a very short period of time.

So you’ve settled on the choice to purchase a LED screen for your setting?. Not a problem it is anymore! As to meet the growing demand for technology, LEDs are neither a luxury commodity nor it is challenging to find these days. From a house television to huge concerts almost all places now use the LED panel screen making a visible difference in the quality of the events.

We actually accept that different advancements (Projection, LCD, and so on) have a spot for huge configuration shows, yet with the most recent degrees of consolidated cost and execution the LED screen is a genuine competitor for a definitive premium showcase alternative. Our desire for this article is to assist you with understanding the subsequent stages in choosing the best LED screen for your scene.

LED Screen Processo

The LED screen processor is a crucial thing. This proselyte a computerized show signal ((HDMI, DVI, etc) into a LED Screen prepared stream, isolating out every pixel exclusively and sending the privileged data with tones and splendor, and board request and so on A portion of these have pleasant UIs while others are ‘secret elements’ with USB or ethernet control as it were. When your screen is arrangement then you will not typically need to change these once more.

The sign is regularly sent over ethernet (cat5) and can commonly run for ~100m before it will experience an issue. Inside the processor, there are ordinarily a couple of various chipsets utilized (a digit like ‘Intel inside’ a PC). We suggest Novastar, yet Linsn and numerous others likewise give great alternatives.

The vital issue with the LED screen processors is that they don’t have any scaling capacity, for example, change the picture in at any rate. They fundamentally will simply take the upper-left pixel of the approaching sign, furthermore, put it onto the upper left pixel on your drove screen as opposed to ensuring it will fit. We can give preparing on the best way to set these up and will commission and enhance the cycle as part of an establishment.

LED Panel Screen Understanding Optical Performance

Strong state lighting can offer unmatched execution whenever joined by the correct focal points and reflectors.

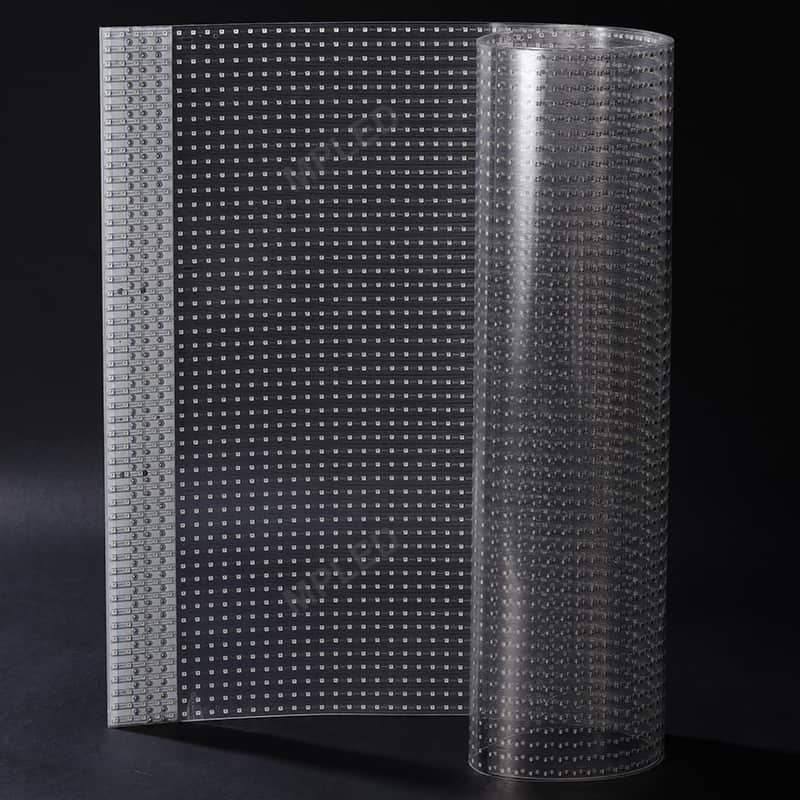

High-quality optics are an essential component of an LED panel screen. Without high-quality optics, it is no less than a bouquet without roses. Similarly, most of the light of the LED screen vanishes if you use it with an unsuitable device. LEDs rather than being conventional functionally emit lights in various forms. Incandescent light bulbs are multidirectional illuminating in 360 degrees while LEDs illuminate 180 degrees only as they are directional. Typically, a LED display panel comprises of a semiconductor chip (one or more), placed on top of a heat-conducting material; an optic lens, enclosing the chip, and lastly the heat-regulating components.

Omnidirectional light is then captured by the source that itself is surrounded by glass, acrylic reflector, and metal, guiding it into specific distribution. This further allows it to work with optical lenses and similar accessories which leads to the final shaping of the beam.

As the LEDs output is more concentrated than the regular ones it is more difficult for the devices to distribute it over a longer distance. Sometimes it is too broad for the devices which leads to the lack of intensity over distance. Accordingly, LED lights and apparatuses normally join at least one auxiliary optics. It can comprise of focal points, reflectors, complete inward reflection (TIR) optics (a focal point and a reflector), and diffusers that gather the light amplify its force direct it to an objective surface, and afterward obscure it to upgrade pillar and shading consistency.

Reflectors

Reflectors are easier to execute and more affordable to make than TIR optics. How well they collimate light—or spread light into equal beams—depends, partially, on their shape. Faceting or dividing the surface can improve shaft consistency, as can applying various surfaces or wraps up. If necessary, focal points can additionally diffuse the light.

However, reflectors don’t address everything. Light from a LED can avoid allegorical reflectors, for instance, and spill light or, more awful, glare. Besides, numerous reflectors are fume-covers with aluminum, a conductive material that can cause electrical shorting. Manufacturers use Polymeric material for their production. You can apply these movies onto a plastic substrate and are non-conductive, exceptionally intelligent, and optically better than aluminum.

TIR Optics

TIR optics or TIR lenses are based upon the idea or the ancient phenomenon. It states that when a ray of light travels from one medium of higher density to another medium of lower density it bends at an angle and reflects with all of its beam energy. The focal point guides light from the source’s middle to the reflector, which sends it out in a controlled shaft. An extra surface over the get-together gives another chance to adjust the light.

TIR optics profit by attributes that are unique to LEDs. Not at all like incandescents, which transmit heat outward, LEDs send heat out their base. Permitting TIR optics to fit cozily over their domed top. Chris says to Bailey, head of the Lighting Solutions Center at Hubbell Lighting, “LEDs manage the cost of a chance for the fashioner to remove light straightforwardly from the source and unequivocally direct it through key vertical and even planes.”

Size Matters

Shum says that the size proportion of a LED or LED bundle to an optic decides the pillar point. This is, smaller pillars require more modest light sources or bigger optics.

The source sizes expand, drive by a requirement for higher iridescent transition and comfort. To draw in installation creators to their items, LED producers have presented secluded, high-yield, chip-on-board (COB) LED clusters. These clusters are getting more normal and can yield 600 to 20,000 lumens at 6W 200W, Bailey says. COB LEDs comprise various passes in the wire to work as one electrical gadget. It is amassed into an artistic bundle with a solitary transmitting surface. Intended to deliver a particular shading temperature and lumen yield, they remove the mystery from making a very much incorporated LED.

For More Information, Contact Us Today!