Fireproof technology of LED display

The fireproof raw materials of the LED display mainly include the wires used inside the LED display, the power supply, the fireproof materials of the external protective structure and the plastic kit.

(1) In most LED display applications, the larger the unit area of the LED display, the greater the power consumption, and the higher the electrical stability of the wire. Among many wire products, the use of wires that meet the requirements of the national standard can ensure their safety and stability. There are three requirements: the core is a copper wire conductive carrier, the core cross-sectional area tolerance is within the standard range, and the rubber covering the core is insulated. The performance and flame retardancy meet the standard. Compared with the general aluminum core, the core cross-sectional area is too small, and the insulation rubber grade is not enough, the energization performance is more stable, and the short circuit is not prone to occur.

(2) UL-certified power products are also the choice when choosing similar products. Their effective conversion rate can ensure the safety and stability of the power load, and can work normally under the condition of high external ambient temperature.

(3) In terms of materials for the external protective structure of the LED display, most of the LED display products with a higher fire rating on the market use fireproof aluminum-plastic panels, which have excellent fire resistance and strong fire and flame retardancy. Conventional aluminum-plastic The board ages quickly with the impact of high temperature, rain, cold and heat, and rain and dew will easily penetrate into the inside of the screen in a relatively humid climate, causing short circuits in electronic components and causing fires.

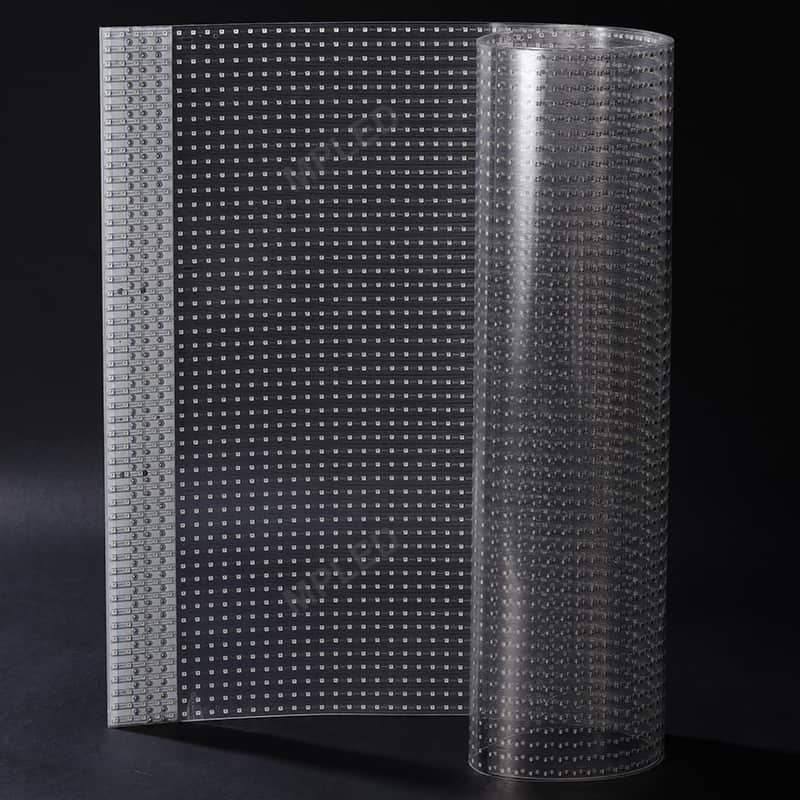

(4) There is another important part of the fireproof raw materials for LED display screens, which is the plastic kit. The plastic kit is mainly the material used for the bottom shell of the unit module mask. The main raw material used is the flame-retardant PC+glass fiber material, which not only has Combustion function, can be used in high and low temperature and long-term use, will not deform, will not become brittle and crack, at the same time, combined with better sealing glue, can effectively block the rainwater from the external environment from penetrating into the interior and cause a short circuit to cause a fire.

In addition to the internal raw materials that will affect the fire protection effect, the external configuration and design are also very important, but the external configuration mainly involves heat dissipation in the fire protection problem. When the LED display is working, an exhaust fan and air conditioner will be configured to cool the inside of the screen. It is recommended to install a 1P air conditioner every 8~10m2 to ensure that the temperature inside the screen maintains a normal constant temperature. Inadequate configuration of the air conditioner or exhaust fan will cause uneven heat dissipation, which may easily lead to hidden safety hazards inside the screen due to temperature rise. At the same time, many LED companies simply simulate the spray waterproof test of the external environment when testing the protection level of the cabinet. The durability and strength of the waterproof effect need to be verified, so after the LED display product has been used for a period of time, there will be The occurrence of water seepage is an important reason why outdoor LED displays are prone to fire or have a short service life. When dealing with thunderstorms, the lightning arrester installed in the screen is an indispensable device to avoid strong lightning strikes and damage the internal components of the screen. The lightning arrester can directly lead the lightning to the ground without affecting the screen.